Open-pit construction

◎ Laying box culverts (pipe culverts) using a self-propelled shield machine for excavationJobs successfully completed as of February 2013: 450

Open-pit shield machine

Jogo-cho, Kakamigahara, Gifu prefecture Shield machine used for rainwater pipeline

Open-pit small machine

Horikawa-cho, Toyama Shield machine used for drainage channels

Open-pit medium machine

Eastern Hashiuchi, Tsu Shield machine used for rainwater pipelines

For further details, please visit the Open Pit Construction Association website.

Take a look at our videos on YouTube.

◎ Construction method overview

This construction method uses a self-propelled shield machine for excavation to lay box culverts. The work is conducted in a continuous cycle of excavating the tunnel; preparing the foundation; laying the culverts (box culverts); and backfilling. On jobs involving laying pipes for drainage systems, constructing storm water drainage pipes, and river improvement construction, we mainly use a method that employs steel sheet piling to retain the earth.

◎ Advantages of construction method

①Retains soil without vibration or sound ②Self-propelling shield can lay a wide variety of pipes (box culverts) without damaging them ③Allows for rapid construction; can greatly reduce building time ④Aperture is restricted to size of the shield machine, so construction area is small ⑤Shield machine (aperture) is mobile, so the effect on the surrounding residents is short-term ⑥Can also line tunnels ⑦Lack of embedments such as stumps means minimal loosening of surrounding soil ⑧More economical compared to traditional methods of construction for defined project lengths (>~150 m) ⑨Allows for curve construction, uneven construction, and simultaneous laying of box culverts & sewage pipes ⑩Simple operation; no skill required ⑪No patent or licensing fees required ⑫No construction-company limitations; anyone can use it ⑬Shield machine available for lease

Before construction

Before construction During construction

During construction After construction

After construction

◎Construction procedure & shield machine self-propulsion

In the open-pit method of construction, the shield machine is self-propelling. The machine can lay all sorts of pipes & culverts, including box culverts, Hume concrete pipes, and FRPM pipes. There’s no need to manufacture special products for use with the shield machine.

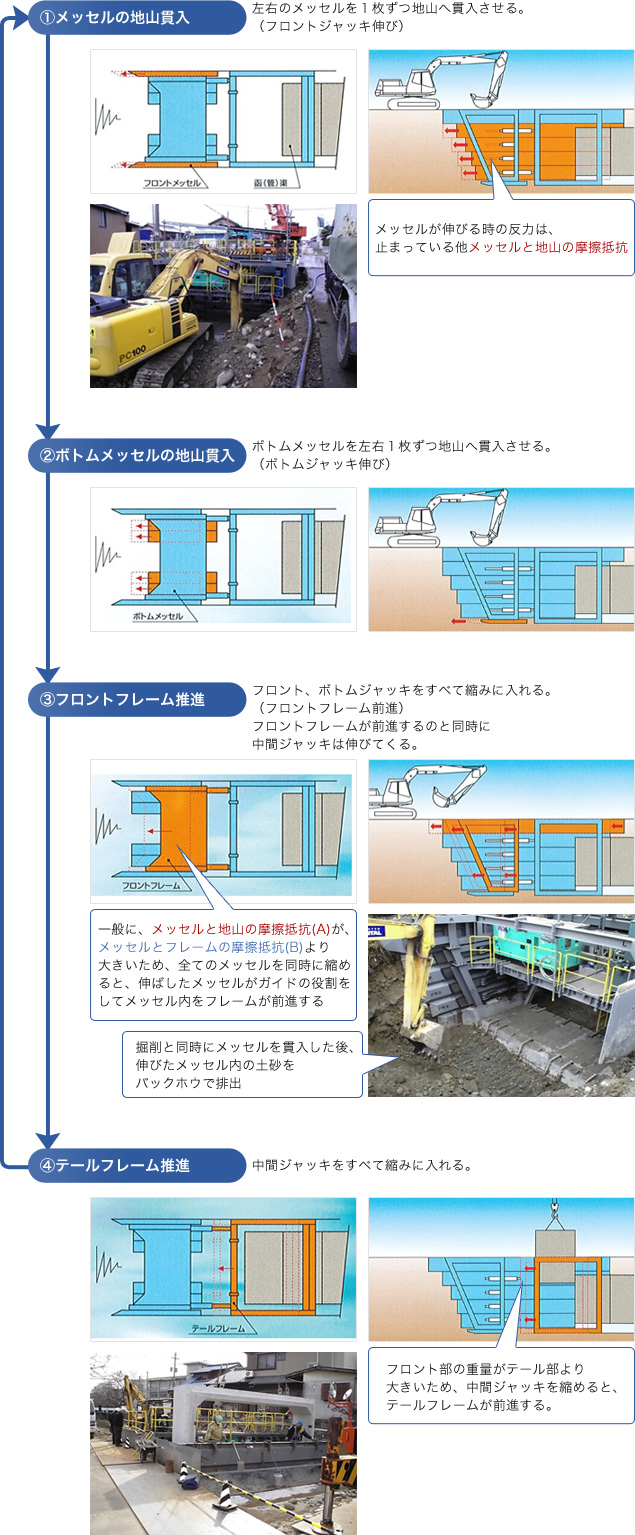

Principles behind the self-propulsion of the open-pit shield machine

The shield machine consists of a cylindrical frame and a series of Messers installed inside around the circumference of the frame’s surface. In general, the key to the machine’s self-propulsion lies in frictional resistance between the shield machine and the surrounding earth; the frictional resistance between the Messers and the earth (A) exceeds the frictional resistance between the Messers and the frame (B). Therefore, when the Messers are extended via the frame, a reactive force is generated from the frictional resistance between the other Messers, which are then immobile, and the ground. Also, when the front frame advances, the Messers, which have been extended one by one, will all retract at once; therefore, using the frictional resistance between the Messers and the ground (A) as a reaction force, the shield frame will advance the interior Messers, where the frictional resistance (B) is smaller.

oundation work & backfilling

oundation work & backfilling Construction

Construction Surveying

Surveying Backfilling & compacting projects

Backfilling & compacting projects

◎Introduction to construction sites

The open-pit construction method can get results in site conditions that would pose problems for traditional methods of construction, such as repairs of existing waterways, construction adjacent to buildings, soft ground, and stiff ground where it is difficult to drive steel sheet piling.

Seto, Aichi prefecture Road improvements on the Fukagawa-Anada line

Foundation work in soft ground

In recent years, this method has been used in conjunction with the top base method with projects on soft ground.

Gifu Waterway improvement work (Showa-cho drainage channel)

Laying a box culvert in a residential area

With excavations at depths exceeding 2.5 m, we recommend the Open-Pit Small. At about 35,000 yen per meter, it’s affordable, with minimal construction time and impact on the surrounding earth.

Odawara, Kanagawa prefecture Rainwater drainage project

Laying of box culverts on National Route 1 (lining method)

The lining girders are loaded onto the shield machine; since construction is conducted at night, the roadway is unobstructed in the daytime. The positions of the girders are adjusted to suit the overburden, making it possible to set the lining plates flush with the road.

Tsubata-machi, Kahoku-gun, Ishikawa prefecture Funabashigawa repair work

Repair work on established waterways. Being able to leave the shield machine underground enabled the three years’ continuous construction necessary for the project to be performed.

Improvement of a waterway that ran through a residential district and widening of the road. When the water level in the waterway rises, or at the end of the year’s construction work, only the shield machine itself remains underground; only the hydraulic units need to be collected.◎Introduction to construction sites 2

Kakamigahara, Gifu prefecture Jougo-cho main rainwater pipe construction

Working on a layer of boulders

Construction on sites where use of traditional construction methods would be difficult due to the presence of boulders and nearby houses

Construction near homes

Construction near homesKumamoto Sugihara-cho flood 7-chome road improvement project

Laying a U-shaped flume

As shown in the photo, in addition to box culverts, the shield machine can also lay U-shaped flumes and FRPM pipe.

Tsu, Mie prefecture Eastern Hashiuchi, 2nd drainage district, main rainwater pipe construction project

Construction on one highway lane only

Earthquake-proof box culverts were used here. Construction took place on only one lane of the highway, and the entire surface was opened up for the lining work

SJ and DCJ box culverts can be used

SJ and DCJ box culverts can be used